Product Characteristics of Wire-Wound Resistors

I. Introduction

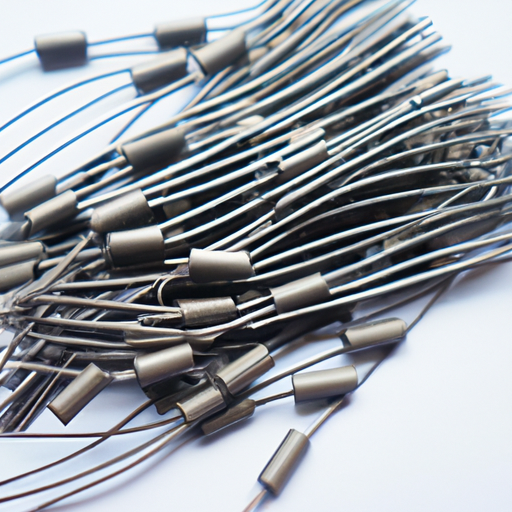

Wire-wound resistors are a type of resistor that is constructed by winding a metal wire around a core. This design allows for precise resistance values and excellent thermal stability, making them a popular choice in various electronic applications. Resistors, in general, play a crucial role in electronic circuits by controlling current flow, dividing voltages, and providing biasing for active components. This article aims to explore the product characteristics of wire-wound resistors, including their structure, electrical and performance characteristics, advantages and disadvantages, and their applications in different industries.

II. Basic Structure of Wire-Wound Resistors

A. Composition and Materials Used

Wire-wound resistors are primarily made from a metal wire, which is typically composed of materials such as nickel-chromium or copper-nickel. These materials are chosen for their excellent conductivity and resistance properties. The wire is wound around a non-conductive core, which is often made from ceramic or plastic, providing insulation and mechanical support.

B. Construction Methods

The construction of wire-wound resistors involves specific winding techniques that can affect their performance. The wire can be wound in various configurations, such as helical or spiral, depending on the desired resistance value and application. Additionally, wire-wound resistors can be mounted in different orientations, including axial and radial, allowing for flexibility in circuit design.

III. Electrical Characteristics

A. Resistance Value Range

Wire-wound resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. They also come with various tolerance levels, which indicate how much the actual resistance can deviate from the specified value. Standard resistance values are often available, making it easier for designers to select the appropriate resistor for their needs.

B. Power Rating

The power rating of a wire-wound resistor is a critical characteristic that defines how much power the resistor can dissipate without overheating. This rating is significant because exceeding it can lead to resistor failure. Factors affecting power rating include the resistor's size, construction materials, and cooling methods. Proper selection of power ratings is essential for ensuring reliable circuit operation.

C. Temperature Coefficient of Resistance (TCR)

The temperature coefficient of resistance (TCR) measures how much a resistor's resistance changes with temperature. For wire-wound resistors, TCR is typically low, meaning they maintain stable resistance values across a range of temperatures. This stability is crucial in applications where temperature fluctuations can affect circuit performance.

IV. Performance Characteristics

A. Stability and Reliability

Wire-wound resistors are known for their long-term stability and reliability. They can withstand environmental factors such as humidity, temperature changes, and mechanical stress better than many other resistor types. This durability makes them suitable for demanding applications where consistent performance is required.

B. Frequency Response

The frequency response of wire-wound resistors is another important characteristic. They exhibit low inductance and capacitance, which allows them to perform well at high frequencies. This property is particularly beneficial in applications such as RF circuits and audio equipment, where signal integrity is paramount.

C. Noise Characteristics

Wire-wound resistors generate less noise compared to other resistor types, such as carbon film or metal film resistors. The noise generated by resistors can affect the performance of sensitive circuits, making wire-wound resistors a preferred choice in precision applications.

V. Advantages of Wire-Wound Resistors

A. High Precision and Accuracy

One of the primary advantages of wire-wound resistors is their high precision and accuracy. They can be manufactured to very tight tolerances, making them ideal for applications that require exact resistance values.

B. Excellent Thermal Stability

Wire-wound resistors exhibit excellent thermal stability, which means their resistance values remain consistent even when subjected to temperature variations. This characteristic is crucial in applications where temperature changes are common.

C. Capability to Handle High Power Loads

Wire-wound resistors can handle high power loads, making them suitable for applications such as power supplies and motor control circuits. Their ability to dissipate heat effectively allows them to operate safely under high power conditions.

D. Low Inductance and Capacitance

The low inductance and capacitance of wire-wound resistors make them ideal for high-frequency applications. This characteristic helps maintain signal integrity and reduces the risk of distortion in sensitive circuits.

VI. Disadvantages of Wire-Wound Resistors

A. Size and Weight Considerations

One of the main disadvantages of wire-wound resistors is their size and weight. Compared to other resistor types, such as surface-mount resistors, wire-wound resistors can be bulkier, which may limit their use in compact electronic designs.

B. Cost Factors Compared to Other Resistor Types

Wire-wound resistors are generally more expensive than other types of resistors, such as carbon film or metal film resistors. This cost factor can be a consideration for manufacturers looking to minimize production expenses.

C. Limited Resistance Values in Some Applications

While wire-wound resistors are available in a wide range of resistance values, there are limitations in certain applications. For example, very high resistance values may not be feasible with wire-wound technology, necessitating the use of alternative resistor types.

D. Sensitivity to Mechanical Stress

Wire-wound resistors can be sensitive to mechanical stress, which can affect their performance and reliability. Care must be taken during installation and operation to avoid damaging the resistor.

VII. Applications of Wire-Wound Resistors

A. Industrial Applications

Wire-wound resistors are widely used in industrial applications, including power supplies and motor control circuits. Their ability to handle high power loads and maintain stability under varying conditions makes them ideal for these environments.

B. Consumer Electronics

In consumer electronics, wire-wound resistors are commonly found in audio equipment and measurement devices. Their low noise characteristics and high precision make them suitable for applications where sound quality and accuracy are critical.

C. Automotive and Aerospace Applications

Wire-wound resistors are also utilized in automotive and aerospace applications, such as engine control units and navigation systems. Their reliability and performance in extreme conditions make them a preferred choice in these demanding fields.

VIII. Conclusion

In summary, wire-wound resistors are characterized by their precise resistance values, excellent thermal stability, and ability to handle high power loads. While they have some disadvantages, such as size and cost, their advantages make them suitable for a wide range of applications in various industries. Selecting the right resistor for specific applications is crucial for ensuring optimal circuit performance. As technology advances, wire-wound resistor technology continues to evolve, promising even greater performance and reliability in the future.

IX. References

1. Academic papers and articles on resistor technology.

2. Industry standards and guidelines for electronic components.

3. Manufacturer specifications and datasheets for wire-wound resistors.

This comprehensive overview of wire-wound resistors highlights their significance in electronic design and their role in ensuring reliable circuit performance across various applications.