What is the Working Principle of Resistor Manufacturers?

I. Introduction

Resistors are fundamental components in electronic circuits, serving as the backbone of electrical engineering. They are designed to limit the flow of electric current, divide voltages, and protect sensitive components from excessive current. The importance of resistors cannot be overstated; they are found in virtually every electronic device, from simple household appliances to complex computing systems. This blog post will delve into the working principles of resistor manufacturers, exploring the materials, processes, and innovations that define this essential industry.

II. Understanding Resistors

A. Basic Functionality of Resistors

At the core of a resistor's functionality is Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R). This relationship is expressed mathematically as:

\[ V = I \times R \]

Resistors play a crucial role in current limiting and voltage division. By introducing resistance into a circuit, they can control the amount of current that flows, ensuring that components receive the appropriate voltage levels. This is particularly important in protecting sensitive devices from damage due to excessive current.

B. Types of Resistors

Resistors come in various types, each designed for specific applications:

1. **Fixed Resistors**: These resistors have a constant resistance value and are the most commonly used type. They are available in various materials and power ratings.

2. **Variable Resistors (Potentiometers)**: These allow for adjustable resistance, making them ideal for applications like volume controls in audio equipment.

3. **Specialty Resistors**: This category includes thermistors, which change resistance with temperature, and photoresistors, which vary resistance based on light exposure. These resistors are used in specialized applications such as temperature sensing and light detection.

III. Materials Used in Resistor Manufacturing

A. Conductive Materials

The choice of materials is critical in resistor manufacturing, as they directly affect performance and reliability. Common conductive materials include:

1. **Carbon Composition**: Made from a mixture of carbon and a binding material, these resistors are known for their stability and low cost.

2. **Metal Film**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer high precision and low noise, making them suitable for high-frequency applications.

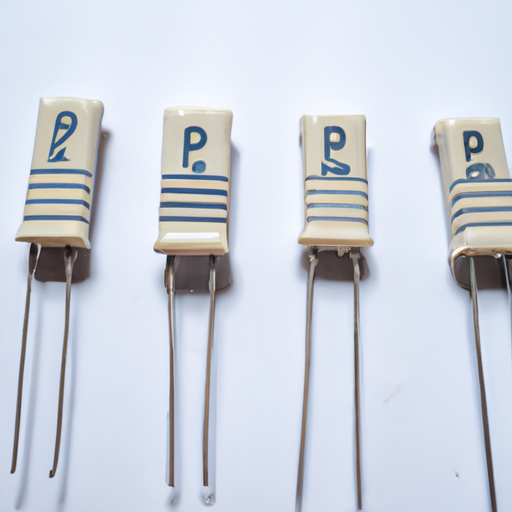

3. **Wirewound**: Constructed by winding a metal wire around a ceramic or plastic core, wirewound resistors can handle high power levels and are often used in power applications.

B. Insulating Materials

Insulating materials are equally important in resistor manufacturing, as they prevent unwanted current flow and ensure safety. Common insulating materials include:

1. **Epoxy Resins**: These are used for coating and encapsulating resistors, providing protection against moisture and mechanical damage.

2. **Ceramic**: Often used as a substrate for resistors, ceramic materials offer excellent thermal stability and electrical insulation.

3. **Other Insulating Compounds**: Various other materials, such as silicone and glass, may also be used depending on the specific requirements of the resistor.

IV. The Manufacturing Process of Resistors

A. Design and Engineering

The manufacturing process begins with design and engineering. Manufacturers must define specifications and requirements based on the intended application of the resistors. This phase often involves prototyping and testing to ensure that the design meets performance standards.

B. Material Preparation

Once the design is finalized, the next step is material preparation. This involves sourcing raw materials and employing various processing techniques to prepare them for fabrication. For example, carbon may be ground into a fine powder for carbon composition resistors, while metal films are deposited onto substrates using vacuum deposition techniques.

C. Fabrication Techniques

The fabrication of resistors varies based on the type being produced:

1. **Carbon Composition Resistors**: These are made by mixing carbon powder with a binding agent, forming a paste that is then shaped and cured.

2. **Metal Film Resistors**: A thin film of metal is deposited onto a ceramic substrate, which is then etched to create the desired resistance value.

3. **Wirewound Resistors**: A metal wire is wound around a core, and the ends are connected to terminals. The wire's resistance is determined by its length, thickness, and material.

D. Assembly and Packaging

After fabrication, resistors undergo assembly and packaging. This includes mounting the resistors onto circuit boards or packaging them for distribution. Quality control measures are implemented at this stage to ensure that each resistor meets the required specifications.

V. Quality Assurance in Resistor Manufacturing

A. Testing Procedures

Quality assurance is a critical aspect of resistor manufacturing. Manufacturers employ various testing procedures to ensure reliability and performance:

1. **Electrical Testing**: This involves measuring the resistance value, tolerance, and temperature coefficient to ensure compliance with specifications.

2. **Environmental Testing**: Resistors are subjected to various environmental conditions, such as temperature and humidity, to assess their performance under real-world conditions.

B. Standards and Certifications

To maintain high-quality standards, resistor manufacturers adhere to various industry standards and certifications, including:

1. **ISO Standards**: These international standards ensure that manufacturers follow best practices in quality management.

2. **RoHS Compliance**: This directive restricts the use of certain hazardous substances in electrical and electronic equipment, ensuring that resistors are safe for consumers and the environment.

3. **Other Industry Standards**: Manufacturers may also comply with specific standards relevant to their target markets, such as automotive or aerospace industries.

VI. Innovations and Trends in Resistor Manufacturing

A. Advances in Materials Science

Recent advancements in materials science have led to the development of new resistor types with improved performance characteristics. For example, the use of nanomaterials can enhance the thermal stability and electrical properties of resistors.

B. Automation and Smart Manufacturing

The integration of automation and smart manufacturing technologies is transforming the resistor manufacturing process. Automated systems can improve efficiency, reduce production costs, and enhance quality control through real-time monitoring.

C. Sustainability Practices in Resistor Production

As environmental concerns grow, many resistor manufacturers are adopting sustainable practices. This includes using eco-friendly materials, reducing waste, and implementing energy-efficient manufacturing processes.

VII. Conclusion

In summary, resistors are essential components in electronic circuits, and their manufacturing involves a complex interplay of materials, design, and engineering. Understanding the working principles of resistor manufacturers provides valuable insights into the importance of these components in technology. As the industry continues to evolve with innovations in materials science and manufacturing processes, the future of resistor manufacturing looks promising, ensuring that these vital components will remain at the forefront of electronic design and application.

VIII. References

- Academic Journals on Electrical Engineering

- Industry Reports on Resistor Manufacturing Trends

- Manufacturer Websites and Technical Documentation on Resistor Types and Applications

This comprehensive exploration of resistor manufacturing highlights the intricate processes and innovations that contribute to the production of these vital electronic components. As technology advances, the role of resistors will continue to be pivotal in shaping the future of electronics.